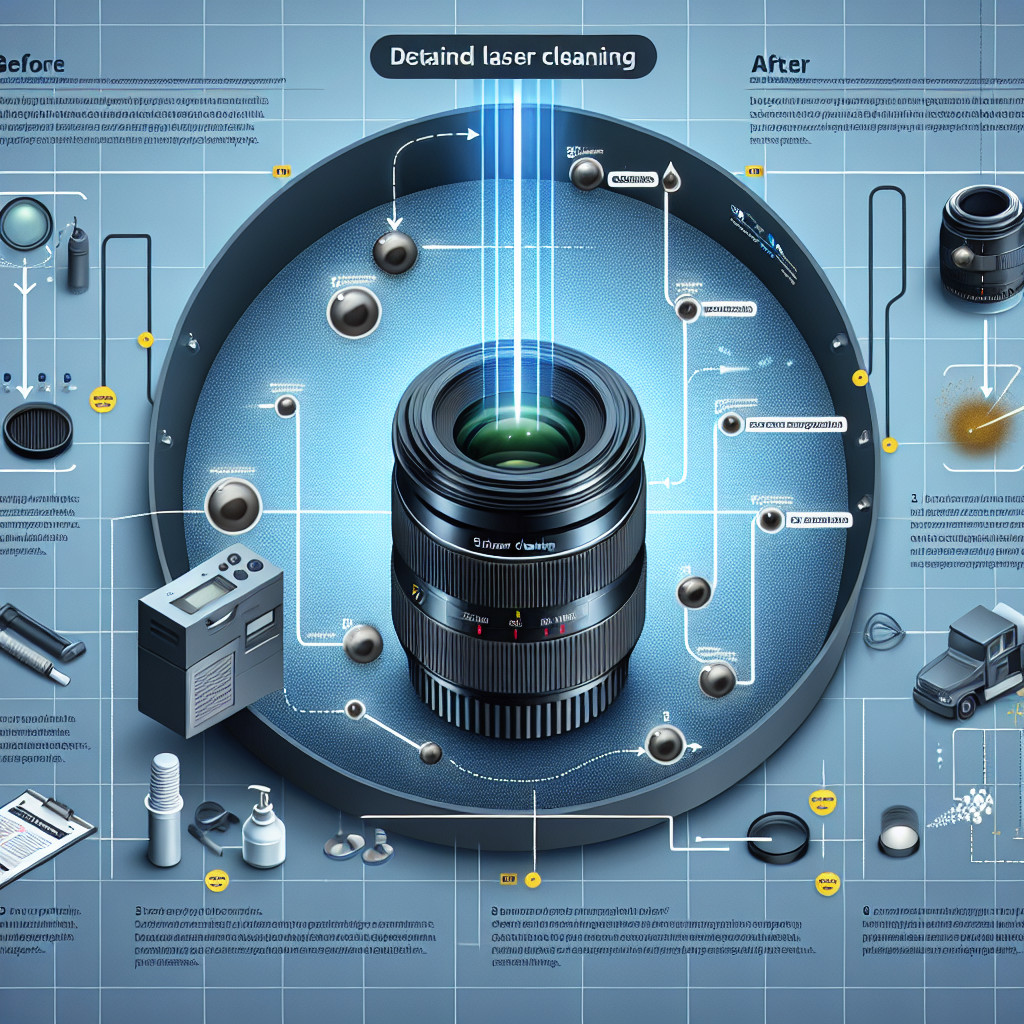

Laser cleaning for removing contaminants from optical lenses

- Benefits of Laser Cleaning for Optical Lenses

- Comparison of Laser Cleaning vs Traditional Cleaning Methods for Optical Lenses

- How Does Laser Cleaning Work on Optical Lenses?

- The Importance of Removing Contaminants from Optical Lenses

- Common Contaminants on Optical Lenses and How Laser Cleaning Can Help

Benefits of Laser Cleaning for Optical Lenses

Benefits of Laser Cleaning:

| Benefit | Description |

|---|---|

| Non-contact cleaning | Laser cleaning does not require physical contact with the lens, reducing the risk of damage. |

| Precision cleaning | Laser cleaning can target specific areas of the lens with high precision, ensuring thorough cleaning. |

| No residue | Laser cleaning leaves no residue behind, eliminating the need for additional cleaning steps. |

| No chemicals | Laser cleaning does not require the use of chemicals, making it environmentally friendly. |

| Fast cleaning | Laser cleaning is a quick process, saving time and increasing productivity. |

| Long-lasting results | Laser cleaning provides long-lasting cleaning results, reducing the frequency of cleaning maintenance. |

Overall, laser cleaning offers a range of benefits for cleaning optical lenses, making it a preferred choice for many industries. Whether you need to clean camera lenses, microscope lenses, or telescope lenses, laser cleaning can provide a fast, efficient, and effective solution.

Comparison of Laser Cleaning vs Traditional Cleaning Methods for Optical Lenses

Traditional Cleaning Methods

Traditional cleaning methods for optical lenses involve using a microfiber cloth to wipe away dust and dirt. In some cases, cleaning solutions may be used to remove stubborn stains or residues. While these methods are effective to some extent, they can also pose risks to the lens surface. Improper cleaning techniques or the use of harsh chemicals can scratch or damage the lens, affecting its optical performance.

Laser Cleaning

Laser cleaning is a non-contact, non-abrasive method that uses high-energy laser pulses to remove contaminants from the surface of optical lenses. The laser beam is directed at the lens surface, where it vaporizes the contaminants without causing any damage to the lens itself. Laser cleaning is highly precise and can remove even the smallest particles without leaving any residue behind.

Comparison

- Effectiveness: Laser cleaning is more effective than traditional methods in removing contaminants from optical lenses. It can reach areas that are difficult to access with a cloth and can remove even the smallest particles with precision.

- Safety: Laser cleaning is a safer option for cleaning optical lenses as it does not involve any physical contact with the lens surface. Traditional cleaning methods, on the other hand, can pose risks of scratching or damaging the lens.

- Speed: Laser cleaning is a faster method compared to traditional cleaning methods. It can clean lenses in a fraction of the time it takes to wipe them with a cloth or use cleaning solutions.

- Cost: While laser cleaning may have a higher upfront cost due to the equipment involved, it can be more cost-effective in the long run as it reduces the need for frequent replacements or repairs due to damage caused by traditional cleaning methods.

Conclusion

Overall, laser cleaning is a superior method for cleaning optical lenses compared to traditional cleaning methods. It offers greater effectiveness, safety, speed, and cost-efficiency. As technology continues to advance, laser cleaning is likely to become the preferred choice for maintaining the cleanliness and performance of optical lenses in various industries.

How Does Laser Cleaning Work on Optical Lenses?

What is Laser Cleaning?

Laser cleaning is a non-contact, environmentally friendly cleaning method that uses a high-energy laser beam to remove contaminants from surfaces. The laser beam is focused on the surface of the lens, where it vaporizes the contaminants without affecting the underlying material. This process is known as ablation, and it leaves behind a clean and undamaged surface.

How Does Laser Cleaning Work on Optical Lenses?

When laser cleaning optical lenses, a specific wavelength of laser light is used to target the contaminants on the surface of the lens. The laser beam is directed at the lens, where it heats up and vaporizes the contaminants, such as dust, dirt, or grease. The energy from the laser beam is absorbed by the contaminants, causing them to break down and be removed from the surface of the lens.

One of the key advantages of laser cleaning is its precision. The laser beam can be focused on specific areas of the lens, allowing for targeted cleaning without affecting the rest of the surface. This level of precision is especially important for delicate optical lenses, where even minor damage can impact their performance.

Benefits of Laser Cleaning on Optical Lenses

- Non-contact cleaning: Laser cleaning is a non-contact method, which means that there is no physical contact between the cleaning equipment and the lens. This reduces the risk of damage to the lens and ensures a gentle cleaning process.

- Environmentally friendly: Laser cleaning does not require the use of chemicals or solvents, making it an environmentally friendly cleaning method. It also produces minimal waste, as the contaminants are vaporized and removed from the surface.

- Efficient and effective: Laser cleaning is a fast and efficient cleaning method that can remove even stubborn contaminants from optical lenses. It can be used on a wide range of materials, including glass, plastic, and metal.

- Precision cleaning: Laser cleaning allows for precise cleaning of optical lenses, ensuring that only the contaminants are removed without affecting the underlying material. This level of precision is essential for maintaining the performance of the lens.

Conclusion

Laser cleaning is a safe, efficient, and environmentally friendly method for cleaning optical lenses. By using a high-energy laser beam to vaporize contaminants on the surface of the lens, laser cleaning can effectively remove dirt, dust, and other contaminants without causing any damage. This precision cleaning method is essential for maintaining the performance and longevity of optical lenses in various industries.

The Importance of Removing Contaminants from Optical Lenses

Effects of Contaminants on Optical Lenses

Contaminants on optical lenses can have a significant impact on their performance. Dust and dirt particles can block light from passing through the lens, resulting in blurry or distorted images. Oils from fingerprints or other sources can create smudges on the lens surface, further degrading image quality. In addition, contaminants can also cause scratches or other damage to the lens, reducing its lifespan and effectiveness.

Methods of Cleaning Optical Lenses

There are several methods for cleaning optical lenses, depending on the type and severity of the contamination. One common method is to use a lens cleaning solution and a microfiber cloth to gently wipe away dirt and oils from the lens surface. It is important to use a gentle touch and avoid using harsh chemicals or abrasive materials that could damage the lens.

Another method for removing contaminants from optical lenses is to use compressed air to blow away dust and dirt particles. This can be particularly effective for removing loose particles that are not stuck to the lens surface. However, it is important to use caution when using compressed air, as excessive pressure can damage the lens or push contaminants further into the lens.

Importance of Regular Cleaning

Regular cleaning of optical lenses is essential to maintain their performance and ensure the quality of the images they produce. Contaminants can build up over time and become more difficult to remove, leading to a decrease in image quality and potentially causing permanent damage to the lens. By regularly cleaning optical lenses, you can prolong their lifespan and ensure that they continue to produce clear, sharp images.

Conclusion

Removing contaminants from optical lenses is a crucial step in maintaining their performance and ensuring the quality of the images they produce. By using gentle cleaning methods and regularly cleaning your lenses, you can prevent the buildup of dust, dirt, oils, and other particles that can degrade image quality and damage the lens. Taking care of your optical lenses will not only improve the quality of your images but also prolong the lifespan of your lenses, saving you time and money in the long run.

Common Contaminants on Optical Lenses and How Laser Cleaning Can Help

Optical lenses are essential components in a wide range of industries, including manufacturing, healthcare, and research. However, over time, these lenses can become contaminated with various substances that can affect their performance. Some of the most common contaminants found on optical lenses include:

1. Dust and dirt: Dust and dirt particles can accumulate on optical lenses over time, reducing their clarity and affecting the quality of the images they produce.

2. Fingerprints: Fingerprints are another common contaminant on optical lenses, especially in environments where lenses are frequently handled. Fingerprints can leave oily residues on the lens surface, leading to smudges and reduced image quality.

3. Oil and grease: Oil and grease can also build up on optical lenses, particularly in industrial settings where machinery and equipment are in use. These substances can be difficult to remove and can affect the lens’s ability to transmit light effectively.

4. Water spots: Water spots can form on optical lenses when they come into contact with moisture, such as during cleaning or in humid environments. These spots can distort images and reduce the lens’s performance.

5. Chemical residues: Chemical residues from cleaning solutions or other substances can also contaminate optical lenses, leading to discoloration or damage to the lens surface.

Fortunately, laser cleaning technology offers a highly effective solution for removing contaminants from optical lenses. Laser cleaning uses a focused beam of light to vaporize contaminants on the lens surface, leaving behind a clean and undamaged surface. Here are some of the benefits of using laser cleaning for optical lenses:

1. Precision: Laser cleaning allows for precise control over the cleaning process, ensuring that only the contaminants are removed without damaging the lens surface.

2. Efficiency: Laser cleaning is a fast and efficient process, making it ideal for cleaning large numbers of lenses quickly and effectively.

3. Non-contact cleaning: Laser cleaning is a non-contact process, meaning that there is no physical contact between the cleaning equipment and the lens surface. This reduces the risk of damage to the lens and ensures a thorough cleaning.

4. Environmentally friendly: Laser cleaning is a clean and environmentally friendly process, as it does not require the use of harsh chemicals or solvents.

5. Versatility: Laser cleaning can be used to remove a wide range of contaminants from optical lenses, including dust, dirt, fingerprints, and chemical residues.

In conclusion, optical lenses can become contaminated with a variety of substances that can affect their performance. Laser cleaning offers a highly effective and efficient solution for removing contaminants from optical lenses, ensuring that they remain clean and clear for optimal performance. By using laser cleaning technology, industries can maintain the quality and longevity of their optical lenses, leading to improved productivity and performance.

- Laser cleaning for removing contaminants from optical lenses - 30 July 2024

- The cost-effectiveness of laser cleaning compared to other methods - 17 April 2024